F.A.Q.

What is LTL shipping

LTL (less-than-truckload) freight shipments consist of goods, commodities, or cargo that weighing more than 100 lbs. Usually, they are palletized, boxed, or created and moved by a pallet jack or hand cart. This method is economical because it only requires a portion of the trailer space. LTL shipments are grouped together with other shipments for consolidation and deconsolidation. The rates for LTL shipments are based on distance, delivery speed, load density, and accessorial services such as additional insurance, appointments for pickup/delivery, lift gates, residential pickup/delivery, and airport pickup/delivery. These accessorial services will incur additional charges by the carrier and can be priced into the quote. LTL shipments are categorized into different freight classes based on size, weight, density, and value. Though transit times may be longer than full truckload shipments, carriers strive to provide reliable delivery schedules. The National Motor Freight Classification system is commonly used to classify LTL shipments. LTL shipments are normally handled by authorized contract carriers such as Saia LTL Freight, Southeastern, FedEx Freight, XPO, ACT, R&L Carriers, and more. These Carriers operate warehouse terminals within the shipping area. Your shipment may be unloaded and reloaded several times during its journey. For more Information on NMFC Packaging requirements, Download our PDF

How do I determine my freight calss?

What is a freight class/NMFC code?

Classes are a freight shipping industry standard. They’re set by the NMFC tariff, which is a publication for motor carriers containing rules, descriptions and ratings of all commodities.

Your freight class helps determine your shipping cost.* It’s calculated based on how difficult your commodity is to ship and how much liability is involved

You’ll need your freight class code in order to get a rate quote.

Note: When you ship items with different classes on the same pallet, the shipment defaults to the highest class of those items. For example, if you’re shipping car accessories (class 60) with car covers (class 100) on the same pallet, the entire pallet is class 100

Higher volume shippers may wish to invest in classing software available from the NMFTA titled ClassIT®

How to determine freight class

Freight class is calculated according to your commodity’s transportation characteristics, including

- Density — How much it weighs in relation to its size

- Liability — Its value and whether extra security precautions are needed to safeguard it against theft or damage

- Handling — If it requires special loading equipment or precautions

- Stow-ability — How it fits in the trailer with other freight

There are 18 classes, numbered 50 to 500.

A lower class number generally means a lower shipping cost. However reclassing and document corrections after pickup can cost even more than to original or correct class at booking! CARRIERS WILL CHECK THE WEIGHT AND DENSITY! Remember, when you weigh your shipment, include the pallet or other packaging.

FREIGHT CLASS LIST

FREIGHT CLASS

FREIGHT DECRIPTION

WEIGHT per ft3

Class 50

Clean Freight – Dense and heavy items that are difficult to handle, such as bricks or tiles. Durable freight that fits on a standard 4′ × 4′ pallet

50+ lbs

Class 55

Bricks, cement, hardwood flooring, construction materials.

35-50 lbs

Class 60

Car accessories and parts, boxed books, bottled drinks

30-35 lbs

Class 65

Car accessories and parts, auto engines, food items

22.5-30 lbs

Class 70

Car accessories and parts, auto engines, food items

15-22.5 lbs

Class 77.5

Tires, bathroom fixtures

13.5-15 lbs

Class 85

Crated machinery, cast iron stoves

12-13.5 lbs

Class 92.5

Computers, monitors, refrigerators

10.5-12 lbs

Class 100

Car covers, canvas, boat covers, wine cases, caskets

9-10.5 lbs

Class 110

Cabinets, framed art, table saws

8-9 lbs

Class 125

Small home appliances

7-8 lbs

Class 150

Auto sheet metal, bookcases

6-7 lbs

Class 175

Clothing, couches, stuffed furniture

5-6 lbs

Class 200

Sheet metal parts, aluminum tables, packaged mattresses, aircraft parts

4-5 lbs

Class 250

Mattresses and box springs, plasma TVs, bamboo furniture

3-4 lbs

Class 300

Model boats, assembled chairs, tables, wood cabinets

2-3 lbs

Class 400

Low Density or High Value Freight – Deer antlers

1-2 lbs

Class 500

Very Low Density or Very High Value Freight – Very low-density items or very high-value items, such as feathers or ping pong balls

<1 lbs

LTL vs. PTL (Partial Truckload)

Partial truckload falls between LTL and full truckload, typically involving shipments over 1,000 pounds or 3 or more pallets. PTL involve less handling, and result in faster transit times. The shipper will not have exclusive use of all cargo space of the asset hired.

Partial truckload shipments generally do not require a freight class in order to secure a rate. Rates are calculated by asset availability, shipping lane rate, mileage, weight & amount of space required. Example, 50 % of asset spaced used would equate to 50% of the normal FTL shipping rate for that shipping lane.

What is an FTL (Full Truckload)

Full Truckload Shipping can reduce transportation times if your product volumes can fill up or nearly fill the entire asset. Truckload Shipping allows you to have exclusive use of the hired asset to transport your product. Rates are calculated by current asset availability, time frame, shipping lane rate history, mileage, weight and asset type.

What types of assets are available and how much cargo can it carry?

Dry Van – 48-53 feet long with a typical maximum cargo capacity of 44,000-46,000 lbs. A 53′ long van can generally hold 26 standard 42″x48″ skids when they are “turned.” A skilled shipper may be able to fit 30 40″x48″ skids. If your product is lightweight, you may be able to stack them as well. The width of the van can vary between 96″ and 101″ on the inside, while the height can vary between 96″ and 110″ inside. Shorter length trailers of 28-36′ are also used in the LTL industry.

Refrigerated Van – 48-53 feet long 40,-44,000 lbs. have insulated walls and self-powered refrigeration units. Reefers are commonly used to transport food and other temperature-sensitive goods. Perishable goods may include products like fresh produce, dairy, and medicines.

Flatbed Trailers typically has a length of 48-53 feet and can carry between 45,000-50,000 lbs of cargo. The standard flatbed has a deck height of 5 feet and a width of 98-102 inches, allowing for a maximum loading width of 8’6” without a permit. In most states, cargo is limited to a length of 3 feet beyond the end of the trailer, with a permit required for longer cargo. In some states, cargo can extend beyond the front of the trailer. For oversized cargo, such as over width, over height (13’6″-14 feet), and over length, permits must be obtained in all states driven, at an additional expense. Escorts may also be required for some oversized loads, further adding to the cost. Flatbed trucks offer versatility in cargo security, with the ability to tarp most cargo and use a variety of securement methods, such as chains, straps, and dunnage.

Flatbed Stretch – 48-83 feet long 45,000-50,00 Lbs. An extendable or “stretch” deck trailer is similar to the standard flatbed trailer but has a built-in sliding mechanism offering the ability to extend the length of the cargo bed. These are ideal for items that need more space and or support lengthwise. permits and escorts are normally required with this type of trailer.

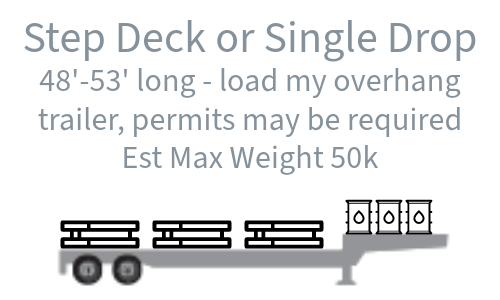

Step Deck – Similar to a flatbed however a step deck offers a lower deck for the majority of the deck, 30′-42′ of lower deck space. The typical height is 3′, allowing for taller cargo before permits are required. Step deck trailers can also help with odd shaped cargo with the use of levelers and supports.

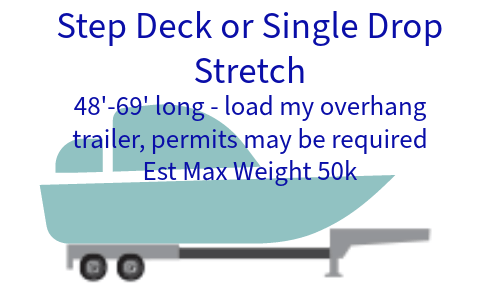

Step Deck Stretch – 48-69 feet long 45,000-50,000 Lbs. An extendable or “stretch” step deck trailer is similar to the step deck trailer but has a built-in sliding mechanism offering the ability to extend the length of the cargo bed. These are ideal for items that need more space and or support lengthwise. permits and escorts are normally required with this type of trailer.

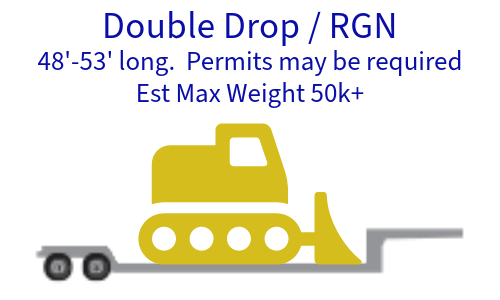

Removable gooseneck or double-drop trailer is a specialized semi-trailer used to transport oversized and heavy cargo. Its detachable front end, the “gooseneck,” allows for easy loading and unloading. The main deck is low to the ground and has multiple axles to distribute weight and comply with regulations. Ramps are often included for loading heavy equipment. These trailers are used in the transportation of machinery, agricultural equipment, construction materials, wind turbine components, in the oil and gas industry, modular buildings, bridge beams and girders, and utility equipment. The removable gooseneck design makes them an indispensable tool for industries dealing with large and cumbersome cargo.

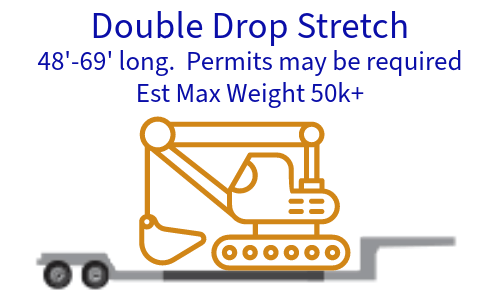

Double Drop Stretch trailer is a type of truck trailer used to move very large cargo. It is designed especially to handle items that are too long or heavy to fit on smaller trucks. The trailer has three parts: an upper deck, a main deck, and a rear deck. The main deck is low to the ground, which helps keep the truck stable when carrying big items. The length of the main deck and the rear deck can be adjusted so that items of different sizes will fit. The trailer usually has many wheels and axles so it can handle the weight of extremely heavy cargo. It can be used to move heavy machines, bridge beams, wind turbine blades, aerospace parts, and other big items that cannot be transported easily.

Retractable curtain Trailers provide flexibility, convenience, and protection for various cargo types. Its curtain-side design and retractable mechanism allows for easy access during loading and unloading. The trailer has both a solid roof and floor, providing protection from above and below. This design is especially beneficial when handling palletized goods, loose cargo, or goods that require side access.

Box Trucks are versatile vehicles used across various industries for transporting goods, equipment or materials. They have an enclosed cargo area that comes in different sizes. Some models have roll-up doors or hydraulic lifts, while others have climate control systems for temperature-sensitive items. These features make loading and unloading cargo easy. Box trucks are a popular choice for businesses due to their combination of durability, versatility and convenience.

Hotshots are a specialized freight transportation service that uses smaller trucks for expedited delivery of time-sensitive or smaller loads. Vehicles used, range from pickup trucks to medium-duty trucks like flatbeds or gooseneck trailers. Hotshots are popular for regional and local routes, having the ability to accommodate various types of freight, and handling less-than-truckload shipments for industries, including oil and gas, construction, manufacturing, and utilities. They ensure faster delivery times and last-mile delivery, essential for emergency freight, especially during natural disasters or emergencies.

Hotshots are an excellent option for smaller or crowded locations due to their size. Some carriers use fully enclosed trailers. These enclosed trailers are great the shipment of motor vehicles. Availability and capabilities of hotshots can vary greatly. The weight and height of the load may affect the shipping rate due to the smaller vehicle and fuel consumption. The need for ramps or a winch will also affect the rate due to limited availability. Hotshots can also be permitted for oversized loads within their weight range

Sprinter Vans are popular commercial cargo vans due to their versatility, spacious cargo capacity, and various configurations. Key characteristics include multiple sizes and configurations to suit different cargo needs.

Sprinter vans are one of the fastest ways to deliver 1/2 ton -1 ton of cargo. 1-2 maximum pallet capacity. Drivers of sprinter vans are more agile and less regulated than other comercial vehicles. If you need just a few pallets delivered fast, this is the way to do it.

What determines the freight rate?

Freight rates, the prices charged for the transportation of goods or cargo, are determined by several factors that reflect the costs associated with moving goods from one location to another. The specific elements that influence freight rates can vary depending on the mode of transportation (e.g., trucking, rail, air, maritime), and the type of cargo being shipped. Here are some of the key factors that determine freight rates:

1. Distance: The distance between the origin and destination points is a fundamental factor in determining freight rates. Longer distances generally result in higher shipping costs due to increased fuel consumption, wear and tear on equipment, and labor expenses.

2. Time: The time it takes to pick up and deliver a shipment plays a big part in rate calculation. Shippers or receivers may be asked to compensate carriers due to delays in loading or unloading. The industry normally expects to be loaded or unloaded within a 2-hour timeframe or less. Extra stops for pickup or delivery will incur a fee for this added time and mileage.

3. Weight and Volume: The weight and volume of the cargo being shipped are critical factors. Heavier and bulkier cargo often requires specialized equipment or may be subject to weight-based pricing.

4. Freight Class: For less-than-truckload (LTL) and some other modes of transportation, the freight class of the cargo is used to determine rates. Freight classes are assigned based on the density, stowability, handling, and liability of the goods, and they directly impact shipping cost.

5. Mode of Transportation: The chosen mode of transportation, whether it’s trucking, rail, air, maritime, or a combination of these, significantly influences the freight rate. Different modes have varying cost structures and transit times.

6. Fuel Costs: Fluctuations in fuel prices can have a direct impact on freight rates, especially in the trucking industry. Higher fuel prices generally result in higher shipping costs.

7. Equipment Type: The type of transportation equipment used can affect the rate. For example, specialized equipment, such as refrigerated trailers or flatbeds, may come with additional charges.

8. Availability: The availability of the requested assets within the market area and the requested timeframe will also affect the rate. If a carrier must come from farther away, they will want to be compensated in the rate. A higher ratio of freight to available assets will increase the market rate. Sometimes having flexibility in shipping requirements can mean a lower rate.

9. Accessibility and Location: The ease of access to pickup and delivery locations, as well as the location itself (e.g., urban, rural, remote), can impact freight rates. Difficult-to-reach or remote areas often incur higher transportation costs.

10. Seasonal Demand: Seasonal fluctuations in demand can affect freight rates. For example, rates for shipping holiday-related goods may be higher during peak seasons.

11. Market Conditions: General market conditions, including supply and demand for transportation services, can influence rates. Tight capacity and high demand tend to drive up rates, while excess capacity can lead to lower rates.

12. Regulations and Compliance: Regulatory requirements, such as safety regulations, oversize permits and escorts, environmental standards, and border/customs compliance, can lead to additional costs that are passed on to shippers.

13. Special Handling Requirements: Cargo with special handling needs, such as tarps, winches, loading ramps, hazardous materials, or fragile items, may require additional precautions and costs.

Overall, freight rates are determined by a complex interplay of these factors, and they can vary widely based on the specific circumstances of each shipment. A shipment from Ohio to South Carolina will have a different rate from South Carolina to Ohio. Shippers, carriers, and logistics professionals work together to calculate and negotiate freight rates that are fair and economically viable for all parties.

How can I get better freight rates?

Getting the best freight rates for your shipments requires a combination of strategies, negotiation skills, and understanding of the factors that influence pricing in the transportation industry. Here are some steps you can take to secure competitive freight rates:

- Plan Ahead:

Whenever possible, plan your shipments well in advance. Lastminute or urgent shipments tend to command higher rates. - Optimize Packaging and Loading:

Efficiently pack and load your cargo to maximize the use of available space and reduce the risk of damage. This can help you avoid additional charges for unused space or damage claims. - Consolidate Shipments:

Consider consolidating multiple smaller shipments into a single larger one. This can often lead to better pricing because it reduces handling and transportation costs per unit. - Know Your Cargo:

Understand the weight, dimensions, and freight class of your cargo. Accurate and detailed information will help carriers provide more precise quotes. - Choose the Right Mode:

Select the most appropriate mode of transportation for your shipment. Depending on the distance and nature of your cargo, trucking, rail, air, or maritime transport may be the most cost effective option. - Use a Freight Broker:

Consider working with a freight broker. They have industry expertise, established carrier relationships, and negotiation skills to help you find competitive rates. - Negotiate Agreements:

If you have a high volume of shipments, negotiate long term contracts or agreements with brokers and or carriers. These can provide preferential rates based on your commitment. - Be Flexible with Pickup and Delivery Times:

Flexible pickup and delivery windows can help carriers optimize their schedules, potentially resulting in more competitive rates. - Consider Intermodal Transport:

For long distance shipments, explore intermodal transportation options that combine different modes (e.g., truck and rail) for cost savings. - Monitor Market Conditions:

Keep an eye on market conditions, including supply and demand fluctuations. Be prepared to adjust your shipping strategies accordingly to take advantage of favorable rates. - Build Strong Relationships:

Developing long term relationships with carriers can lead to better rates over time. Reliable and consistent business can make you more attractive to carriers. - Stay Informed About Regulations:

Stay updated on industry regulations and compliance requirements. Failure to comply with regulations can result in fines and increased costs.

Remember that the freight industry is dynamic, and rates can vary based on market conditions, so it’s essential to regularly assess your shipping strategies and adapt as needed to secure the best freight rates for your specific circumstances.